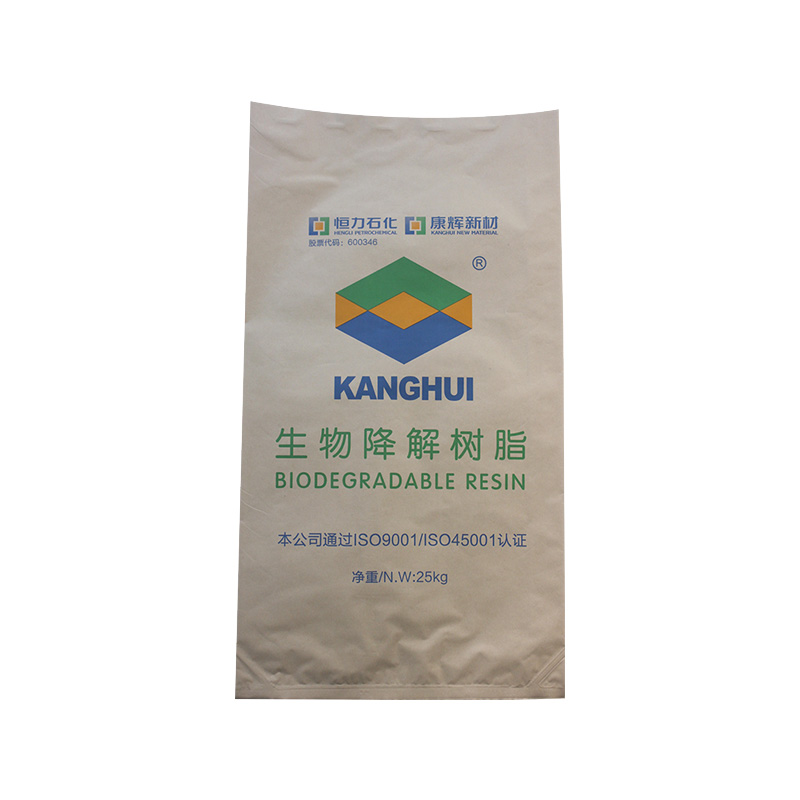

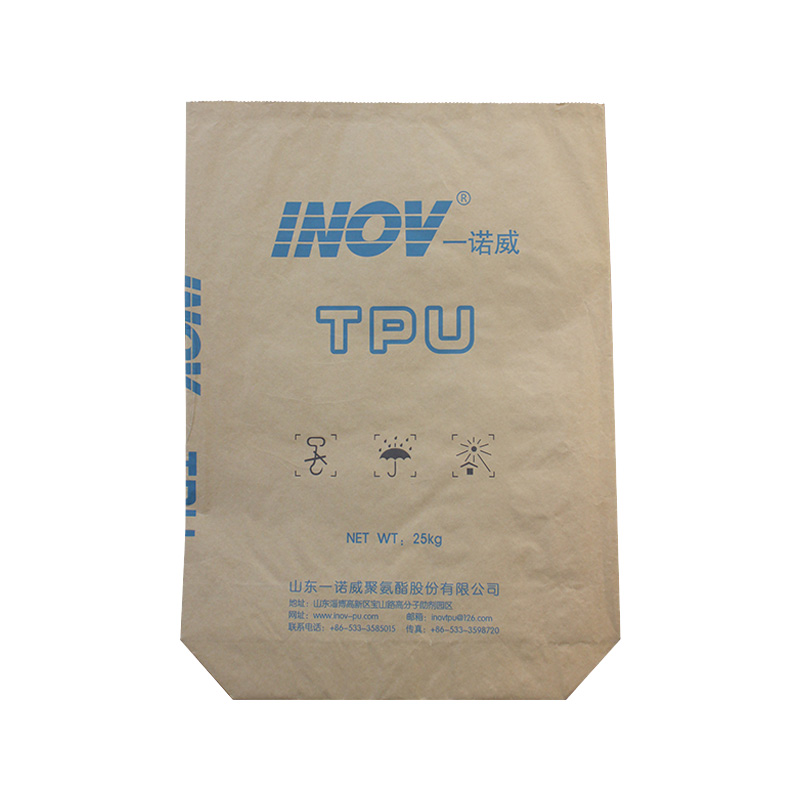

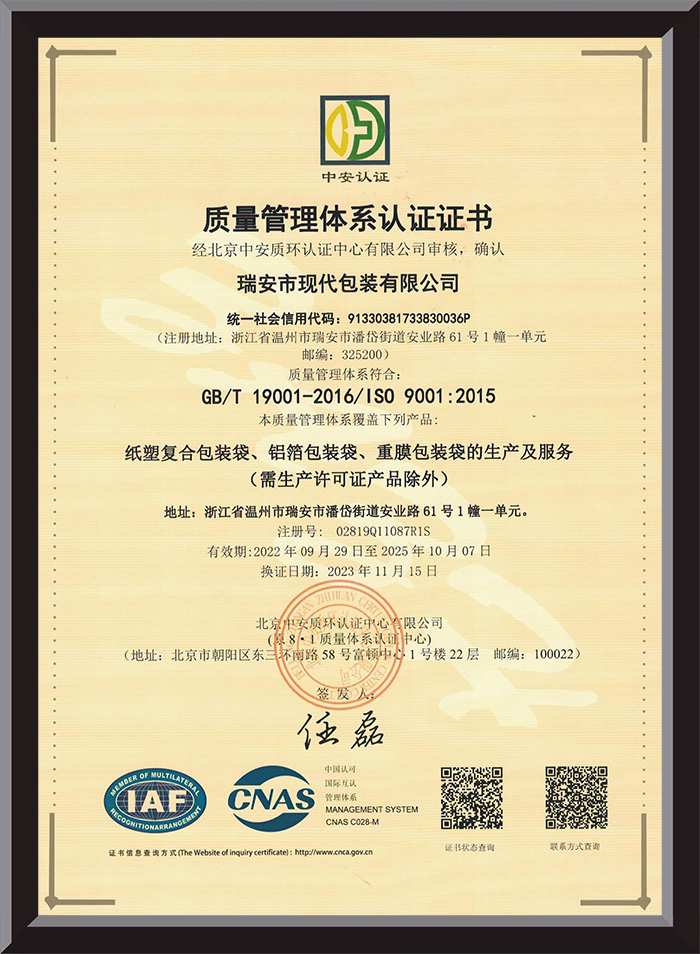

The Flat mouth paper-plastic composite bag is a versatile and durable packaging solution designed for storing and transporting a wide range of materials. Made from a composite of kraft paper, PE (polyethylene), AL (aluminum), and PET (polyethylene terephthalate), this bag is engineered to offer superior protection against punctures, moisture, and light. With a capacity of 20kg-25kg, it is ideal for a variety of industrial applications, including packaging TPU, cable materials, nylon, engineering plastics, and biodegradable plastics. The bag’s flat mouth design makes it easy to fill and seal, while its customizable features allow for tailored solutions to meet specific storage needs.

Product Features

1. Robust Construction

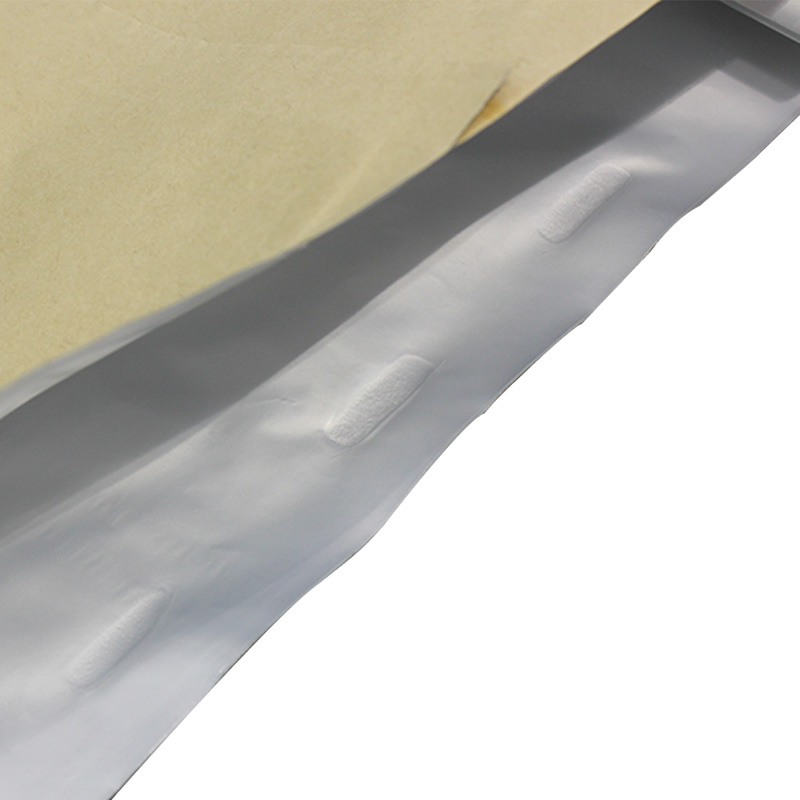

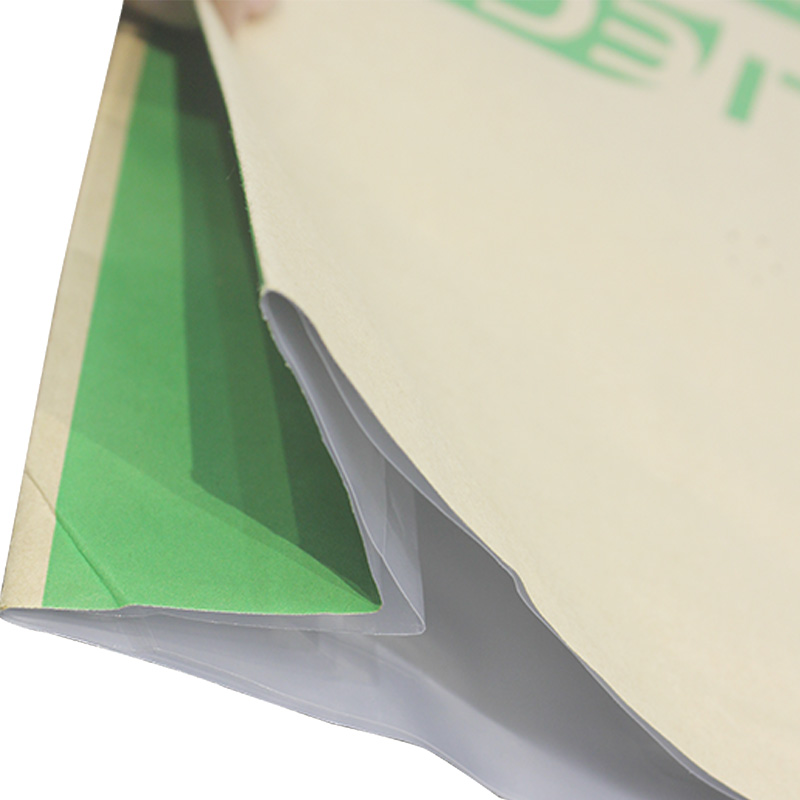

- The Flat mouth paper-plastic composite bag features a multi-layer construction that combines kraft paper for exterior strength with inner layers of PE and AL for additional durability and protection. This composition ensures the bag can withstand heavy loads and rough handling.

- The bag’s design is puncture-resistant, making it highly suitable for sharp or dense materials that may otherwise tear through traditional packaging options.

2. Moisture and UV Resistance

- Equipped with an AL layer, the Flat mouth paper-plastic composite bag effectively blocks out moisture and UV light, preserving the integrity of moisture-sensitive contents such as TPU and PVC. This feature ensures long-term storage without the risk of product degradation.

- The PE inner lining adds an extra layer of protection, creating a moisture-proof barrier that keeps the contents dry in varying environmental conditions.

3. Customizable Design

- The Flat mouth paper-plastic composite bag offers customizable options, including color, weight, and dimensions. This flexibility makes it suitable for industries with unique packaging requirements, ensuring the bag meets exact specifications.

- Additionally, the bag can be fitted with a one-way air valve for products that require controlled ventilation, enhancing its adaptability to different packaging needs.

Product Selling Points

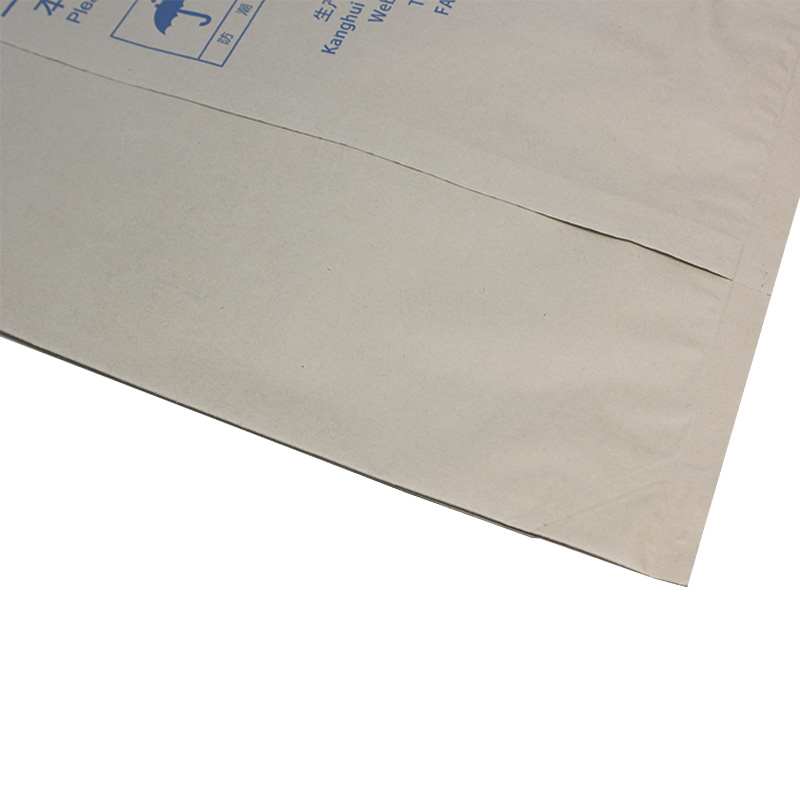

1. Easy-to-Use Flat Mouth Design

- The flat mouth design of the mouth paper-plastic composite bag simplifies the filling process, making it easy to load and seal. This feature reduces operational time and improves efficiency in industrial settings where fast handling is crucial.

- The flat mouth design also allows for uniform sealing, providing an airtight closure that protects the contents from exposure to external elements.

2. Ventilation Option with One-Way Air Valve

- For materials that generate gases or require ventilation during storage, the Flat-mouth paper-plastic composite bag can be equipped with a one-way air valve. This valve allows the release of internal pressure without letting in external moisture, keeping the contents in optimal condition.

- This feature is particularly useful for products like PBAT or nylon, which may require a controlled environment to maintain their quality over time.

Product Applications

1. Industrial Plastics Storage

The mouth paper-plastic composite bag is ideal for storing TPU, nylon 6, nylon 66, and engineering plastics. Its durable design protects against punctures and moisture, while the UV-blocking layer ensures long-term stability.

2. Cable Material Packaging

Perfect for cable insulation compounds, the bag protects from moisture and punctures. Customizable dimensions and easy sealing make it efficient for various cable types.

3. Chemical Packaging

Ideal for chemical additives and resins, the bag's multi-layer design prevents exposure to air and moisture, with an optional one-way air valve for gas release.

4. Biodegradable Plastics

The bag effectively stores biodegradable plastics like PBAT, maintaining integrity with moisture barriers and customization options.

English

English Deutsch

Deutsch 中文简体

中文简体